Sep 12 2016

Ali Abolmaali, Department of Civil Engineering chair and Dr. Tseng Huang Endowed Professor, is leading the team working on the grants, which came after five years of extensive research on the pipes, which are laced with polypropylene synthetic macrofibers. Co-principal investigator Yeonho Park, a UTA faculty research associate, will be instrumental in implementing the pipes in the Texas projects.

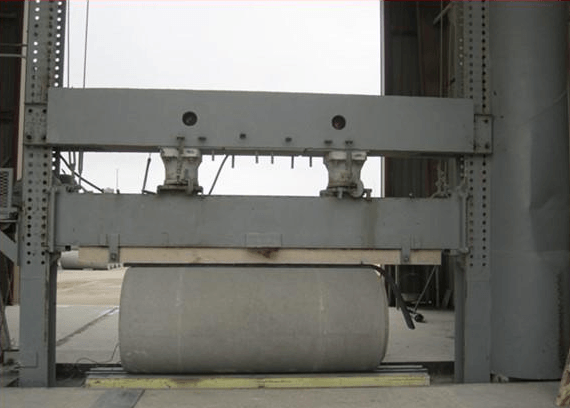

Pipes, reinforced with polypropylene synthetic macrofibers, will be produced and tested at UTA this semester as part of the TxDOT project. Credit: UT Arlington

Pipes, reinforced with polypropylene synthetic macrofibers, will be produced and tested at UTA this semester as part of the TxDOT project. Credit: UT Arlington

The UTA-developed fiber-reinforced pipe meets an American Society for Testing and Materials specification for the first time ever. Abolmaali worked with industry associations and colleagues around the globe to establish that new standard - ASTM C1818 Specification for Synthetic Fiber Reinforced Concrete Culvert, Storm Drain and Sewer Pipe - last year.

The new standard describes a technically strong and durable reinforcement option that can be used for underground piping. The excellent, long-term performance of the concrete pipes reinforced with the polypropylene synthetic macrofiber was observed.

In addition to Abolmaali's team, the American Concrete Pipe Association, its members and Germany-based BASF Construction Chemicals collaborated on the project.

The $800,000 Texas contract is funded through the Texas Department of Transportation. A separate $283,000 contract is funded through the ACPA for developing 100-year service life protocols for synthetic fiber pipes for the Florida Department of Transportation.

Brian Barth, TxDOT's Fort Worth district engineer, said the state agency is excited about trying the new pipe standard.

"We're anxious to see how it does in wet-dry environments," Barth said. "Many of the pilot areas are in rural spots where culverts run alongside the highway, which represent those wet-dry conditions. We'll see how the non-corrosive, fiber-reinforced pipes work in those environments."

Peter Crouch, UTA College of Engineering dean, said this is yet another remarkable example of academia working with industry.

"Dr. Abolmaali and his team deserve a lot of credit for establishing a new American Society for Testing and Materials specification, setting a new national standard in construction that will have very tangible effects industry wide," Crouch said. "His work makes substantial contributions to UTA's focus on sustainable urban communities contained within the Strategic Plan 2020: Bold Solutions | Global Impact."

Several leading concrete pipe producers teamed up with UTA to produce more than 300 full-scale test pipes in different geographical locations within the U.S. with different concrete mix and equipment.

"The UTA-developed fiber pipes first attracted the TxDOT engineers for implementation in Texas for a more durable and resilient infrastructure," Abolmaali said.

UTA and TxDOT will implement the UTA-developed fiber pipes under highways and roadways subjected to vehicle traffic, particularly at locations with junctions of multiple pipes and high underground water tables.

The pipes will be placed in series with conventional concrete pipes in multiple TxDOT construction projects for comparative evaluations.

Abolmaali's team will design, produce and evaluate both types of pipe. A UTA-owned robot will travel through the pipes after the construction to transmit condition assessment data. This evaluation will be conducted for three years so the UTA developed pipes can be tested in real TxDOT projects.

"The UTA fiber pipes will not experience corrosion of reinforcement during its lifetime. That has and will continue to attract many departments of transportation around the county and the world," Abolmaali said. "In addition to TxDOT, we are working with Florida Department of Transportation to implement the UTA fiber pipes in that state. Several other departments of transportation are joining or negotiating with UTA as well."

In addition to TxDOT grant, the American Concrete Pipe Association has awarded Abolmaali's team a $283,000 grant to develop the 100-year service life protocol testing criteria Florida's design specification.

This study includes accelerated aging of UTA-developed fiber pipes for up to 100 years by building a large pool and soaking the pipes in the pool with specific chemicals subjected to high temperature.

"We can simulate the 100-year pipe conditions in only one year," Abolmaali said.

Abolmaali specializes in pipe construction and evaluation. He is currently performing an $882,000 performance evaluation on the city of Arlington's sewer pipes, and then prioritizing which pipes need mending immediately.

He also received a $600,000 grant from the Tarrant Regional Water District to simulate behavior and response of pipe-soil interaction that will surround the 150-mile Integrated Pipeline Project.

Abolmaali was recognized by ASTM with the Spangler Award, which is presented to a member of ASTM C13 who has been highly active technically on the committee, involving themselves in research, authoring research papers, and supplying data and knowledge which changes the existing standards and adds to the development of new standards.

ASTM C13, a committee with a membership of approximately 200, has jurisdiction over 55 national and international standards published in the Annual Book of ASTM Standards.

Source: http://www.uta.edu/