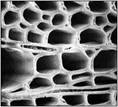

| Timber is a natural material, and each piece tells part of the story of the tree that produced it. Branches that are engulfed by the growing tree cause knots. Insect attack causes the tree to lay down extra wood to protect the tree giving a lump or ‘burl’, or may produce a resin or sap pocket. Fires cause damage that is often reflected in resin pockets, or may result in the tree trying to heal itself by laying down a new cambium that traps bark. These, and other experiences contribute to the character of each piece of wood, and makes each length of timber unique or individual. This individuality gives anything built from the wood a character of its own. Architects can choose to express this individuality by selecting ‘feature’ timber that displays these growth characteristics. On the other hand, some appearance grades limit the extent of natural growth characteristics and result in ‘clear’ timber. ‘Clear’ timber may be chosen where it is necessary to match the colour and appearance of adjacent pieces to give the impression of an unbroken expanse of uniform timber. Cell Structure and Grain All the cells that constitute wood material are formed in the narrow cambium layer, which separates the wood from the bark. The walls of these cells are made up of a network of complex chains of cellulose molecules, which are called microfibrils. When the formation of the cell wall is complete, lignin gradually extends through the cell walls, acting as a bonding agent that “glues” the cells together. The newly formed cells on the inner side of the cambium, become one of the following types of wood tissue: cells fibres, and in hardwoods, vessels. Each of these tissue types performs one or more of the following specific functions: • vessels occur in hardwood timber only and conduct water and dissolved mineral salts from the roots to the leaves. These transmitted fluids provide the basic “raw materials” for photosynthesis.cells store food materials and water, and in softwood species also perform the same conduit function as the vessels do in hardwoods • fibre is a collection of cells and provides mechanical strength of wood;

Most of the cells are vertical in the tree trunk and together form fibres which are elongated particles with the long axis parallel to the longitudinal axis of the trunk (and the lengths of timber when sawn). These fibres form the “grain” of the timber. Other cells are laid down radially. (They go from the centre of the tree outwards to the bark – much like spokes in a wheel.) The rays hold the other fibres together, transfer shear in the growing tree, and ultimately affect shrinkage and other properties of sawn wood. Apart from extractives, there are three main chemical components of wood: cellulose, hemicelluloses and lignin: • Cellulose represents about 40-45% of wood and is a long chain molecule (one dimensional) generally oriented parallel to the long axis of the cell, • Hemicelluloses about 15-30% of hardwoods and about 20% of softwoods. It is a derivation of cellulose that is a two dimensional (planar) organic molecule, • Lignin comprises 22-30% and is an amorphous substance (like a gel). All these components are formed from the sugars produced in the leaves by photosynthesis. Extractives As the many capillaries that are present between the microfibrils become filled with extractives, the sapwood changes into heartwood. Whilst extractives are not generally a part of the essential wood structure, they are of major importance to wood properties, contributing to colour, taste, odour, density, durability, flammability and moisture absorbency (hydroscopicity). The main types of extractives are polyphenols, oils, fats, gums, resins, waxes, small amounts of starches and some inorganic chemicals. Extractives can be used to make a variety of products including wood glues and stains. Natural Features Knots Where a branch starts to grow out of the trunk of a tree, the newly laid-down wood cells in the trunk have to bend around the branch. This leads to a knot in timber that is cut through the young branch. Knots are a natural feature of timber and in many cases, enhance the appearance of the wood. They invariably reduce the strength of the timber due to two effects: • The wood in the centre of the knot can have similar properties to juvenile wood with the low strength and durability associated with core wood. Effectively a knot introduces some loss of section. • Knots near the edges of the piece can cause deviations of grain near the corners and this can have a significant effect on strength.

The effect of knots on structural performance is a function of where the knots are in the cross-section, and on the size of knot: Even though many arris knots (knots that pass right through a corner) are small, they can reduce structural performance as they are in a very critical location. However, knots near the centre of the piece (well away from the corners) can have little effect on the performance of the timber while enhancing its appearance. As the grain in the wood around the knot is deflected around the knot, it leads to a localised slope of grain in the timber adjacent to the knot. The slope of grain does not necessarily detract from appearance, but slope of grain at the edge of a piece of timber can significantly reduce its tensile or bending strength. In appearance products, the slope of grain can affect the way in which stains and clear surface treatments are absorbed by the timber. This produces attractive effects in the way the timber reflects light. Softwood species tend to have dark coloured knots, so they are often quite obvious, but in many hardwoods, the knots are virtually the same colour as the parent wood, and less noticeable. In some hardwood appearance products, knots may only be noticed once a stain and clear finish is applied. (The different grain direction in the knot accepts the stain and finish differently.) Slope of Grain Localised slope of grain can be caused by knots. Slope of grain can also be caused by a slight bend in the tree, which means that when a straight board is cut out of it, there is a bend in the grain. This tends to be a longer feature and may go unnoticed in an appearance product. Some species of Australian hardwoods (such as Jarrah and Blackbutt) can have “wavy grain”. This gives a very attractive rippled appearance in high surface finish applications.

Where timber is “backsawn”, the slope of grain can give interesting effects in the growth rings that enhance the appearance of the timber for some applications.

Checks and Splits Checks are small cracks in the wood (often as a result of drying or seasoning). They are not deep, and do not continue through the depth of a board. They can make wood unsuitable for appearance use, though they can be filled with appropriate coloured or clear fillers. They reduce the contact between adjacent wood grains, but generally have no affect on structural properties.

Splits are deep cracks that penetrate the entire depth or thickness of the wood. They go from one side of the piece to the other. They can occur in wood due to inappropriate handling or by drying stresses. They are more likely to occur near the ends. They generally make the timber unsuitable for use in appearance applications, and reduce shear strength of structural timber. In some applications, where a rustic appearance is required (eg, unfinished timber poles, or rough sawn timber), some limited splitting will be appropriate. Inclusions Sap veins, bark and other inclusions appear as dark, sometimes soft stripes parallel to the grain. These are all growth characteristics that are sandwiched between the growth rings as the wood is laid down. In limited quantities, these can enhance the appearance of the timber, and where they are accompanied by a surface check or depression, it can be filled with a clear filler.

Where the length of the inclusion is within limits, it has little effect on the strength of the timber. A long inclusion can lead to a discontinuity across the grain that reduces the shear strength of the timber. |